|

|

|

|

|

|

|

|

#1 |

|

President, Innovation Cooling

Join Date: Dec 2009

Posts: 74

|

Introduction

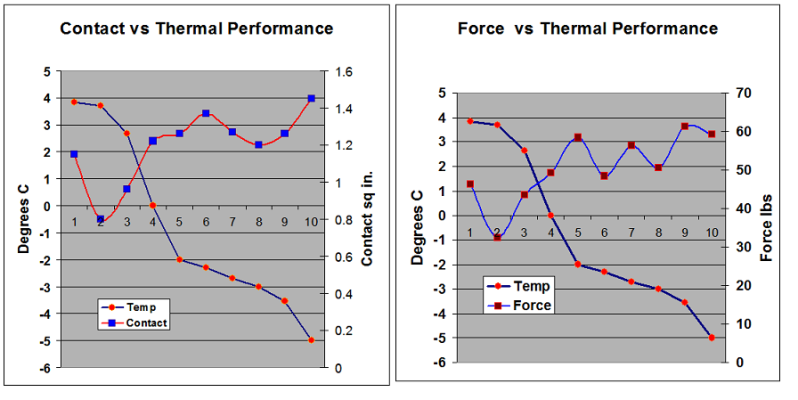

The goal of this competition is to get the best combined contact pressure with the application of the pressure sensitive paper provided through successive iterations to improve your mechanical/thermal contact. Getting the last mile of performance is a non trivial task and will test the patience of the most experienced mechanic. Most people and myself included have approached the problem by lapping IHS and/or sink then tightening sink to where we "think" we have good pressure by indicated temperature readings and we are satisfied if it's tight and we get a couple of degrees of improvement. This best guess method leaves a lot of holes - Are you @ 40 PSI or 60? are you 50% of contact area or 90%? Having a picture of your mount provides a starting point for resolving weaknesses in your set up that might not be apparent otherwise as you can not see what's going on and with this competitive exercise you will become better at analyzing grease contact problems and pressure issues at a glance. Test Instructions The actual test procedure is very simple. Your test kit came with some key envelopes that contain two parts, an A & B plastic film. (Note: Do Not Do The Test with the Thermal Compound Applied) You have been supplied with enough for three tests. 1. Take 1 each of the A & B Samples and place centered on the IHS with the shiny, smooth or uncoated sides facing the metal on the sink and IHS. The coated or frosted sides should facing each other one is the donor and the other is the print. 2. Mount your sink pretty much as you would normally. Be gentle with the paper and try not to abuse it, use clean hands and handle lightly as it can affect your result. 3. Remove the sink and separate the film, one will have a red/pink impression the other will be blank. Throw away the blank the other is the raw result and should look like the Data point 2 &10 below. I recommend visiting Sensor products the film we are using is the Ultra Low (LLLW) with a range of 28 - 85 PSI or (2 - 6 kg/cm˛) we will try to answer any questions although you may want to talk to one of their engineers on some detail you can email "Michael Duer" <[email protected]> http://www.sensorprod.com/pdf/static...lustration.pdf http://www.sensorprod.com/pdf/static/heat_exchanger.pdf http://www.sensorprod.com/pdf/static...a_brochure.pdf http://sensorprod.com/video-gallery/.../pressurex.wmv Cautions 1. Do not get the film wet 2. Treat the film lightly do not abuse - film is sensitive and too much abuse may disqualify the returned sample. Quick notes Return the film entry in one of the key envelopes in one of the plastic bags provided in the self addressed envelope provided You may scan or take a picture of your result and post for comment. one of the best results I have had is data point #10 a one shot with a waterblock with neither heat sink or IHS lapped. Provide thermal tests in conjunction with the pressure tests. The winners will be selected solely on their C/P results, The thermal data is useful for comparisons so please provide it. Hint - Dominant is pressure, so higher pressure increases contact. May the best mechanic win Background As most experienced users understand that when troubleshooting thermal problems there are usually 3 areas of concern. 1.) Pressure 2.) Contact 3.) Application Taking a thermal measurement on it's own is not enough without a relative basis of comparison. Application and use of thermal compound is a mechanical function though many electronically oriented people tend to attach little importance to mechanical measurements. Every thermal compound has it's own unique ideal pressure/thermal performance curve. A highly liquid retail compound with great contact resistance will test well at low or moderate pressures as they hit their Bond line thickness (BLT) or average thickness relatively easily but since they are at optimum at these lower pressures adding more pressure fails to yield much of an improvement. IC Diamond is of a much higher viscosity and has a very different pressure/ performance curve than a more liquid retail compound so at lower pressures and/or contact thermal results maybe equal or less. In paste reviews the major failure is in quantifying the mechanical aspects of what is being tested, are they @ 35lbs and 50% contact area? or 60lbs 60% contact? And how does that relate to multiple thermal/performance pressure curves of different compounds? Note: 80% of sampled retail sinks were over 50lbs psi Quantifying mechanical's is not realistic for the individual user but they get around that by observing multiple user results to mentally average a comparison unlike the individual anecdotal test they have a reference point(s) more or less like we are doing here providing samples for comparison. I generated the attached charts Below from some forum user tests done awhile ago. What they show is what most know already - that good C/P provides a good thermal result. What it also shows is that IC Diamond performance margins increase with over 50 psi force and with good contact margins are higher. Pressure is dominant and contact will increase with pressure. Data point # 2 has weak pressure and poor contact resulting in a + 3.7C increase in temps over the liquid paste. Data point # 10 with great contact and pressure shows a -5C improvement over the more liquid compound. This is a nontrivial approx 9C spread and pretty well explains why people get different results. Also observe Point # 6 it has a somewhat lower pressure but a higher contact hence the improved thermal So to optimize your thermal result, apply enough compound, tighten your sink and do some lapping

|

|

|

|

|

|

#2 |

|

President, Innovation Cooling

Join Date: Dec 2009

Posts: 74

|

It may be worth while doing a few dry runs with some compound (or toothpaste) till you refine your technique - the paste pattern will point you in the right direction if you take some time to look at it

Deciphering thermal compound Contact Patterns Once you understand the cues in contact analysis it is relatively easy to troubleshoot contact and pressure (C/P) issues. The high pressure areas are noted on the right Raw Image as the red\pink highlights and corresponds to the thinner glaze of compound from the paste impression in the higher pressure regions. The areas that that indicate poor contact and pressure in the lab analysis are revealed to be the areas that contain relatively large amounts of compound compared to the high contact areas, likely 200-400% thicker than the optimal bond line (BLT) . The area of the IHS was 1.64 inches and from the lab analysis slightly less than 1/2 the area made contact at the threshold of .80 inches. The pressure film has an operating range 0f 28 psi to 98 psi. So the observation here is in the areas of excess compound the pressure was mostly equal to or below the 28 psi minimum. In the high contact areas in the center and on the edges with the thin paste glaze pressure is at the upper threshold limit and is equal to or greater than 98 psi. Again, an optimal mount would obviously comprise a broad contact pattern with a thin layer/glaze of compound indicating good pressure or at least enough pressure to produce a thin BLT.

|

|

|

|

|

|

#3 |

|

President, Innovation Cooling

Join Date: Dec 2009

Posts: 74

|

So whats' up? I gotta cut out a piece of my liver for a comment?

|

|

|

|

|

|

#4 |

|

OCT Newbie

Join Date: Jan 2010

Posts: 20

|

seeing as i must of posted mine in the wrong section last time il post it again here

well heres what mine looks like  note the greasy finger print where i picked up one side of the paper xD heres what my contact looked like with the old tim on before i cleaned it up. http://img401.imageshack.us/img401/7335/imag0033gy.jpg the sink http://img638.imageshack.us/img638/5261/imag0034o.jpg the ihs http://img163.imageshack.us/img163/6277/imag0043g.jpg thats the base of the heatsink after a clean, isnt it shiney  tbh its not, but it looks it here xD tbh its not, but it looks it here xD

__________________

To view links or images in signatures your post count must be 5 or greater. You currently have 0 posts. To view links or images in signatures your post count must be 5 or greater. You currently have 0 posts. To view links or images in signatures your post count must be 5 or greater. You currently have 0 posts. Last edited by djpc; 11-17-10 at 10:35 AM. Reason: Sorted out your links :) |

|

|

|

|

|

#5 |

|

OCT Member

|

__________________

Intel i5 750 2.4 Ocd to 2.8GHz| Gigabyte P55-US3L Mobo | 4 GB G.Skill Ripjaw 1600 Mhz | 700 Watt Coolermaster PSU Soon to be watercooled Water Cooling Sponsered By Overclockers Tech. |

|

|

|

|

|

#6 | |

|

President, Innovation Cooling

Join Date: Dec 2009

Posts: 74

|

Quote:

|

|

|

|

|

|

|

#7 |

|

OCT Member

|

Oh lovley I love being in the TOP =) ,

I was Useing an EK WaterBlocks Supreme HF Plexi in a i5 750 Asus P7P55 Pro Board

__________________

Intel i5 750 2.4 Ocd to 2.8GHz| Gigabyte P55-US3L Mobo | 4 GB G.Skill Ripjaw 1600 Mhz | 700 Watt Coolermaster PSU Soon to be watercooled Water Cooling Sponsered By Overclockers Tech. |

|

|

|

|

|

#8 |

|

Moderator

Join Date: Jan 2010

Location: Newcastle

Posts: 201

|

Will get mine done over the weekend, been manic with work lately and was at i41 last weekend.

Bry.

__________________

EVGA X58 SLI LE | i7 920 D0 @ 4.4Ghz | 6GB Patriot Viper II 2000Mhz | EVGA 580GTX | 2 Intel 40GB SSD's in Raid0 | Enermax Infiniti 720W Loop 1 Watercool HEATKILLERŽ CPU Rev3.0 1366 Full Copper Block | Thermochill PA120.3 Loop2 Currently redesigning!! To view links or images in signatures your post count must be 5 or greater. You currently have 0 posts. |

|

|

|

|

|

#9 |

|

Lord Meglomaniac

Join Date: Sep 2008

Location: yorkshire

Posts: 2,264

|

I am a little surprised on the negative returns on this. Out of 28 kits sent; only TWO have completed entries. What a dissapointment!

__________________

To view links or images in signatures your post count must be 5 or greater. You currently have 0 posts. First Place Universal Abit 2006 UK OC championships. Second Place at UK Gigabyte OC 2010! |

|

|

|

|

|

#10 |

|

Moderator

Join Date: Dec 2008

Location: Telford, Shropshire (UK)

Posts: 104

|

Have you sent mine? If so, I'm guessing it was to the Telford address. I'm going home this weekend, so I will bring it back with me. If not, PM me and I'll give you my new address again, as I will DEFINITELY do this asap.

|

|

|

|

|

| Bookmarks |

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

| Thread Tools | Search this Thread |

| Display Modes | |

|

|

All times are GMT. The time now is 10:27 AM.

Linear Mode

Linear Mode